Where Rolex is Made – The Secret of Four Swiss Factories

Why does the place of production matter so much when we talk about watches costing tens of thousands of zlotys? As a brand enthusiast, I set out to find out where is Rolex made?

I once read that Rolex produces around 1,000,000 watches a year, but the company has never officially confirmed this. That’s typical for the brand—mystery surrounds every aspect of its operations. Even basic information must be pieced together from various sources.

The “Swiss Made” label isn’t just marketing. It’s a legal requirement, meaning at least 60% of a watch’s value must be created in Switzerland. For Rolex, this standard is far exceeded—virtually everything is produced locally. Swiss heritage guarantees precision, tradition, and quality proven over centuries.

Where is Rolex made? The watchmaking map

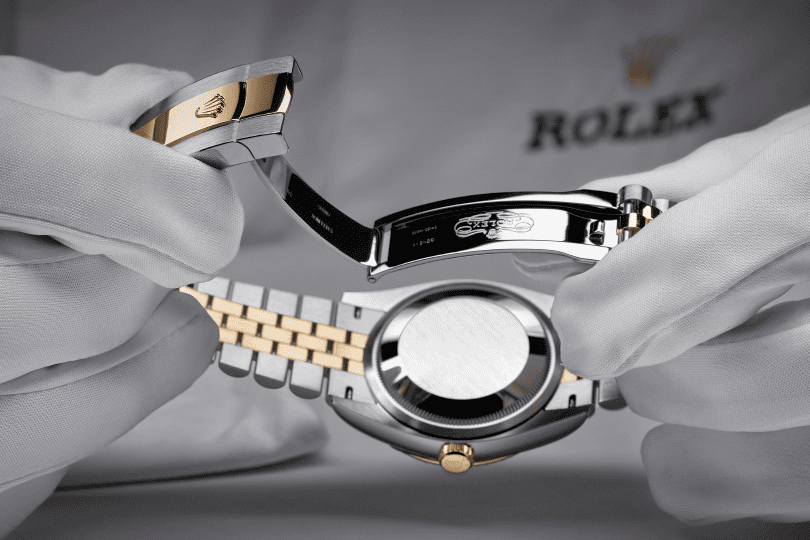

The scale of production is impressive, but the manufacturing process is even more so. Rolex combines cutting-edge automation with traditional craftsmanship. Machines handle operations that demand the utmost precision, but the human eye and hand still oversee the key stages. This combination might sound unusual, but it has worked for decades.

photo: pisa1940.com

The company surrounds its facilities with an air of secrecy. Very few people know what production really looks like from the inside. Photos from the factories appear only occasionally, and interviews with employees are virtually nonexistent. Everything is under strict control.

What exactly goes on behind the walls of Rolex’s Swiss factories? In the following sections, you’ll discover:

• The location and specialization of the four main production sites

• The unique process behind manufacturing each component

• Behind-the-scenes insights into testing and quality control

• The logistics of distributing finished watches

Each facility plays a specific role in this meticulously planned system. It’s time to take a look inside this watchmaking machine.

Four Swiss pillars of production

The four Swiss Rolex facilities form a precisely engineered production machine, with each location assigned a specific role.

| Location | Specialization | Key technology | Fun fact |

|---|---|---|---|

| Plan-les-Ouates | Watch cases, bracelets | Own foundry for Oystersteel and Everose alloys | The only plant with complete control over metallurgy |

| Chêne-Bourg | Watch dials, jewelry | Precise diamond setting | All diamonds undergo 11 stages of inspection |

| Les Acacias | Headquarters and final assembly | Multi-stage quality control | Each watch is tested for a minimum of 15 days |

| Bienne | Clock mechanisms | Full production integration since 2004. | The manufactory produces all the components of the mechanisms |

It’s actually fascinating how they’ve organized everything. In Plan-les-Ouates, the focus is on what you might call the “outer shell” of the watch. That’s where those signature Oyster cases and bracelets are made. But what’s interesting—they have their own foundry there, where they create proprietary metal alloys. That Oystersteel isn’t just regular steel; it’s their special blend. And Everose is their take on rose gold.

Chêne-Bourg handles the things that require a truly delicate touch. The dials, all those tiny details you see up front. If a watch has diamonds, this is where they’re set. Apparently, every stone goes through eleven different inspections—it might sound obsessive, but that’s probably why they sparkle so much.

photo: swiss-architects.com

In Les Acacias, everything comes together. That’s where the headquarters are, and where the finished watches are assembled. Every single piece spends at least fifteen days there undergoing tests—they check water resistance, timekeeping accuracy, shock resistance. Some might think it’s overkill, but apparently, that’s how they’ve done it for decades.

photo: armbanduhren-online.de

Bienne is probably the most interesting place of the four. Since 2004, they’ve had full control over movement production there. Before that, they probably sourced some parts from others, but now they do everything themselves. Every screw, every gear—it’s all made in-house.

photo: watchonista.com

This whole structure makes sense from a logistics perspective. Instead of having one giant facility where everything would get mixed up, they’ve split the processes geographically. Each site can focus on its own specialty and perfect it.

That way, Swiss precision isn’t just a marketing slogan—it’s the tangible result of this kind of work organization, where every facility masters its part of the process.

From London to Geneva – the historic journey of Rolex

The business climate at the beginning of the 20th century was completely different from today. Taxes, social attitudes, wars—all these factors influenced entrepreneurs’ decisions. Hans Wilsdorf, the founder of Rolex, experienced this firsthand.

When he established his company in London in 1905, he probably didn’t expect that he would have to look for a new home for his business. But that’s exactly what happened.

- 1905-1919 – The Great Escape from London

Import taxes on Swiss watch movements became unbearable. On top of that, anti-German sentiment during World War I was on the rise. Despite his German roots, Wilsdorf felt increasingly uncomfortable in England. - 1919 – Geneva as a new beginning

Moving to Geneva opened up new opportunities. Switzerland was neutral, had a watchmaking tradition, and business-friendly laws. - 1926 – Oyster changes everything

The introduction of the waterproof Oyster case was a breakthrough. Geneva became not just the company’s headquarters, but a true hub of innovation. It was here that ideas were born which transformed the industry. - 1960 – The Foundation ensures independence

The creation of the Hans Wilsdorf Foundation was a brilliant move. The company remained private and independent from the whims of the stock market. It was able to steadily develop its production. - 2004 – Bienne completes the puzzle

The full integration of the Bienne factory marked the end of the geographical consolidation process. Four Swiss locations now formed a complete production ecosystem.

Each of these steps influenced the brand’s reputation in a different way. The escape from London might have seemed like a sign of weakness, but it turned out to be a strategic advantage. The Swiss location added prestige and credibility. People associated Switzerland with precision and quality.

The Oyster innovation in Geneva showed that the company didn’t just relocate geographically, but also spread its technological wings. This was important for customers—they saw that Rolex wasn’t running away from problems, but looking for better solutions.

The foundation established in 1960 sent a clear signal to the market. The company was thinking long-term, not chasing quick profits. In the luxury industry, that’s a crucial message.

The integration with Bienne in 2004 marked the end of a certain era. Rolex now had everything under control—from design to final finishing. This geographic production map was shaped by decades of thoughtful decisions.

The brand’s current position on the market is the result of all these moves and reorganizations. From a London startup to a Swiss giant—it’s been a long journey.

What’s next for Rolex production – forecasts and conclusions

Rolex faces some intriguing challenges in the coming years. The company must reconcile its traditional production methods with the modern demands of the market and the environment. This is no easy task, especially when every watch still requires micrometer-level precision.

photo: hodinkee.com

Automation with a human touch will remain essential. Rolex plans to introduce more robots for basic operations—mainly in metalworking and preliminary assembly. However, final finishing, mechanism adjustment, and quality control will stay in the hands of watchmakers. This hybrid approach has worked for years, and there’s no reason to change it. People can still sense things that machines simply can’t detect.

Investments in infrastructure are accelerating, and expansion in Bulle is currently the most likely scenario. The city offers a solid base of skilled workers and proximity to the main facilities. A decision will likely be made within the next two years, as demand for greater production capacity continues to grow steadily.

Sustainability is no longer just a marketing buzzword. Rolex has committed to achieving 95% water recycling in its production processes and using only RJC-certified gold. It sounds ambitious, but the company has a track record of keeping its promises. The cost of these changes will be significant, but social and regulatory pressure leaves no alternative.

Rolex evolves slowly and deliberately. There are no revolutions—just small steps toward modernity. This philosophy has worked for decades and will likely continue to do so. It’s worth watching how the company manages to balance tradition with the future.

OWN marky

lifestyle editor

Luxury Blog

Leave a Comment